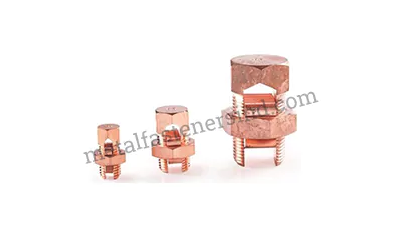

Split Bolts

We are a manufacturer of split bolts including brass split bolts, copper split bolts, aluminium split bolts, bronze split bolts, stud split bolts, solderless split bolts, galvanized split bolts, grounding split bolts, terminal split bolts, electrical split bolts, and more are available in a wide variety of types, sizes, material, threads, finish, head or drive styles. Our range of split bolts and more are widely known for their world-class quality, to serve the best to our domestic as well as international clients. Split Bolts are manufactured and built precisely to fit all your requirements. Every Split Bolts has its own characteristics, advantage, and quality of performance.

Split bolt connectors are wire connectors that consist of an open or split bolt. Split Bolts are coming in various thread forms according to their application. The range of split bolts is also available with various plating, coating, or finishing options including Chrome, Nickle brass, Zinc, Electro Tin, Natural Brass, Tin, or any to increase its performance and durability. Our broad range of split bolts is manufactured to deliver optimum performance, quality, and value.

We provide a wide range of split bolts with European and/or international Standards which have their origins in German DIN Standards especially when it comes to mechanical connecting or fastening elements. DIN Standards are also valid for Split Bolts which don't have ISO and EN Standards. Moreover, we also manufacture and export several Standard Split Bolts including IS Split Bolts, JIS Split Bolts, ASTM Split Bolts, BS Split Bolts, and more. The assortment of Split Bolts is RoHS Compliant, TUV-approved, and UL Listed. The Custom Split Bolts meet customers' samples, design specifications, and performance requirements.

Split bolt connector size chart:

| Main Conductor A mm2 | Tap Conductor B mm2 |

|---|---|

| 10 | 1.5-10 |

| 16 | 2.5-16 |

| 25 | 2.5-25 |

| 35 | 2.5-35 |

| 50 | 2.5-50 |

| 70 | 2.5-70 |

| 90 | 2.5-90 |

| 120 | 10-120 |

| 150 | 10-150 |

| 185 | 50-185 |

| 240 | 95-250 |

Choose the Best Suitable Types of Split Boltsfor Your Industry :

Material:

- Brass (IS 319 type I, BS 249 II, CDA 360, IS 319 III, BS 4183, BS 3643, BS93)

- Copper (BS EN 1982, Copper Alloy C1000, Cast Copper C82000, C87800, ASTM B30-16, B176)4

- Steel (A1, A2, A4, B5, B6, B6X, B7, B7M, B16, L7 L7M, L43, B23, B24, Steel Class 1, 1A, 2: B8, B8A, B8M, B8MA, B8T, B8TA)

- Aluminium (EN AW-1050A, EN AW-1070A, EN AW-1100, EN AW-3103, EN AW-6082)

- Stainless Steel (200 Series, 300 Series and 400 Series)

Threading Methods:

- Thread Cutting, Thread Grinding, Roll Forming, Thread Casting and Molding

Split Bolts Thread Forms:

- ISO Metric, American National screw threads (NC, NF, NS, NPT), American Unified thread Forms (UNC, UNF), British Standard Whitworth thread forms (BSW, BSF) or any Special Threads.

Line Taps Drives:

- Slotted

- Phillips

- Allen

- Star

- Square

- Torx

- Hexagon

- Hex Slotted/Hex Unslotted

- Hex Socket

- Pozidrive

Characteristics:

- Abrasion and Corrosion Resistant.

- Provide long-lasting and dependable performance.

- During the fitting process, the conductor is not distorted or damaged.

- Maximum conductivity and high breakage resistance are provided.

- To ensure dependability, allow for maximum torque.

- UL/CSA standards are met and exceeded.

Industrial Purpose and Use:

- There are numerous applications in various machinery sectors.

- Split Bolts are designed to meet the diverse needs of the machine manufacturing industries.

- Split Bolts used for a variety of copper-to-copper, copper-to-aluminium, and aluminium-to-aluminium conductor applications.

- Applications include grounding, bonding, earthing, and direct burial.

- Ground wires are connected using Split Bolt Connectors.

- Split Bolts connectors are used for a wide range of electrical, electronic, and industrial applications.

Why should you choose us as your split bolts manufacturer?:

- Latest Engineering & Machining technologies

- ISO 9001:2015 Certified Manufacturing and Exporting Company

- Custom Manufacturing Service

- Stringent Quality Check Measures

- Timely Delivery Schedules

- Extensive Manufacturing Facilities

- Contract Manufacturing Service

- Industrious Team

- Competitive Pricing

- We are flexible

As a leading split bolts manufacturing company, we offer:

- An efficient services.

- Ferrous and non-ferrous metal products.

- Design and rapid prototyping.

- Contract manufacturing services.

- 100% inspection before shipment.

- Complete manufacturing solution under one roof.

- Product with variety of materials, finishes, colors, mounting options, and any kind of customization required.

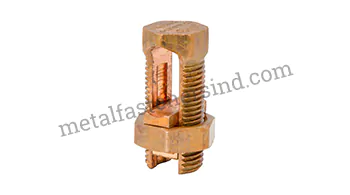

Once the copper wire ends have been stripped, the exposed ends can be placed inside a split bolt connector. The shank of every split bolt connector is open. A bolt's shank is solid.

Split bolt connectors have a nut at the bottom that allows you to tighten the split bolt connector. When you turn it clockwise, the nut will rise, pressing into the wires.