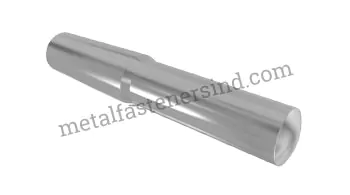

Grooved Pins

Metal grooved pins are solid metal rods with parallel or tapered grooves running axially along their surface. We are manufacturer of Grooved Pins are less elastic but also considerably robust due to their rigid construction. Our Full Range of Grooved Pins is available in a wide variety of sizes, material, threads, finish, head types and styles. Grooved Pins are also known as Mills Pins which are available in a wide range of metric and imperial sizes. Metal Grooved Pins manufactured and built precisely to fit all your requirements. The range of Grooved Pins is also available with various plating, coating or finishing options including Chrome, Nickle brass, Zinc, Electro Tin, Natural Brass, Tin or any to increase its performance and durability.

Grooved Pins are available in various types including Domed Grooved Pins, Parallel Grooved Pins, Socket Grooved Pins, Knuckle Grooved Pins, Straight Grooved Pins, Locking Grooved Pins, Groove Taper Pins and more. We stock a wide range of Grooved Pins with European and/or international Standards which have their origins in German DIN Standards especially when it comes to mechanical connecting or fastening elements. Moreover, we also manufacture and export several Standard Grooved Pins including IS Grooved Pins, JIS Grooved Pins, ASTM Grooved Pins, BS Grooved Pins and more. The range of Grooved Dowel Pins is RoHS Compliant, TUV approved and UL Listed. The Custom Grooved Pins meet customer’s samples, design specification and performance requirements.

Grooved Pins

for Your Industry :Material:

- Steel A1, A2, A4

- Stainless Steel A1, A2, A4

- Carbon Steel

- Mild Steel (MS)

- Brass

- Copper

- Aluminium

Threading Methods:

- Thread Cutting, Thread Grinding, Roll Forming, Thread Casting and Molding

Grooved Pins Thread Forms:

- ISO Metric, American National screw threads (NC, NF, NS, NPT), American Unified thread Forms (UNC, UNF), British Standard Whitworth thread forms (BSW, BSF) or any Special Threads.

Grooved Pins Head Types:

- Round

- Countersunk

- Oval

Characteristics:

- Grooved Pins Are Cylindrical Pins with longitudinal grooves.

- Provide maximum holding power.

- Grooves provide greater surface area.

- Higher pull out resistance.

- Withstand the effect of vibration and shock.

- Provide easy and easy installation.

- Easily driven by hammer or hydraulic press.

- Removable and Reusable.

- Corrosion and Abrasion Resistant.

- Provide precise performance.

Industrial Purpose and Use:

- Grooved Pins used as locking device or locating elements.

- Grooved Pins commonly use to connect the objects with a permanent and reliable connection.

- Used to fix two or more components together.

- Grooved Pins generally used in a variety of applications in automotive, medical, automobile, electrical, electronics, mechanical, manufacturing, construction industrial sectors.

- For a variety of fastening, locating, stopping and alignment applications.