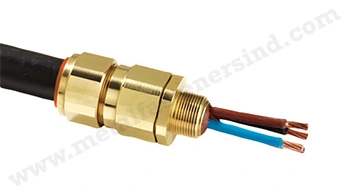

Metal Cable Glands

Metal cable glands are available in a wide variety of sizes, material, threads, finish, shapes, and types. We provide a wide range of standard and high-quality metal cable glands in various metric and imperial sizes. Cable glands are also known as mechanical cable entry devices, cable fittings, and more. Cable glands are generally used to protect and secure cables as they pass through electrical equipment and metal panels. The range of Cable glands are also available with various plating, coating, or finishing options including chrome, nickle brass, zinc, electro tin, natural brass, tin or any to increase its performance and durability. Our broad range of cable glands are manufactured to deliver consistent performance, dimensional accuracy, quality and value.

The range of metal cable glands are available in various types of its depending application. The range of custom cable glands meet customer's samples, design specification, and performance requirements.

Metal Cable Glands

Types of Cable Glands:

Metal Cable Glands

EMC Cable Glands

Explosion Proof Cable Glands

Strain Relief Cable Glands

Weatherproof Cable Glands

Submersible Cable Glands

Flameproof Cable Glands

Flexible Cable Glands

Metric Cable Glands

PG Cable Glands

NPT Cable Glands

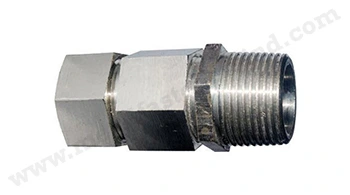

Materials:

- Brass

- Stainless Steel

- Aluminum

- Nickel plated brass

Characteristics of cable glands:

- Cost Effective: Brass cable glands are more affordable than Stainless steel cable glands.

- Corrosion Resistance: Brass cable glands typically offer better corrosion resistance compared to stainless steel cable glands.

- Hygiene: A key difference between brass and stainless steel is that stainless steel is completely lead-free, making it a more hygienic option.

- Strength: Stainless steel cable glands are more durable and have a longer lifespan than brass cable glands.

Industrial purpose and use of metal cable glands:

- Electrical installations: Because of the excellent electrical conductivity of brass cable glands, they are widely used in electrical installations.

- Sealing and Insulation: By providing a sealed connection, cable glands prevent the ingress of dust, dirt, and liquids into electrical enclosures. This is critical in maintaining insulation and preventing short circuits.

- Oil and Gas: Explosion-proof cable glands are crucial for ensuring safety in volatile environments.

- Manufacturing: Used in machinery and assembly lines to manage cables in harsh operating conditions.

- Energy and Utilities: Solar, wind, and power distribution systems utilize cable glands to ensure reliable and secure connections in outdoor and industrial environments.

- Telecommunications: Cable glands help maintain the integrity of data and communication lines, especially in outdoor or underground installations.

- Automotive and Railways: In vehicles and rail systems, cable glands organize and protect wiring systems from heat, vibration, and wear.

- Marine and Offshore: Designed to withstand saltwater, humidity, and high pressures, cable glands are integral to shipbuilding and offshore platforms.